Most vaccines, from measles to Covid-19, require a series of multiple shots before the recipient is considered fully vaccinated. To make that easier to achieve, MIT researchers have developed microparticles that can be tuned to deliver their payload at different time points, which could be used to create “self-boosting” vaccines.

In a new study, the researchers describe how these particles degrade over time, and how they can be tuned to release their contents at different time points. The study also offers insights into how the contents can be protected from losing their stability as they wait to be released.

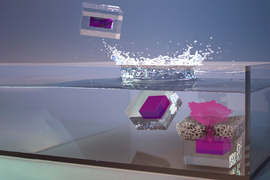

Using these particles, which resemble tiny coffee cups sealed with a lid, researchers could design vaccines that would need to be given just once, and would then “self-boost” at a specified point in the future. The particles can remain under the skin until the vaccine is released and then break down, just like resorbable sutures.

This type of vaccine delivery could be particularly useful for administering childhood vaccinations in regions where people don’t have frequent access to medical care, the researchers say.

“This is a platform that can be broadly applicable to all types of vaccines, including recombinant protein-based vaccines, DNA-based vaccines, even RNA-based vaccines,” says Ana Jaklenec, a research scientist at MIT’s Koch Institute for Integrative Cancer Research. “Understanding the process of how the vaccines are released, which is what we described in this paper, has allowed us to work on formulations that address some of the instability that could be induced over time.”

This approach could also be used to deliver a range of other therapeutics, including cancer drugs, hormone therapy, and biologic drugs, the researchers say.

Jaklenec and Robert Langer, the David H. Koch Institute Professor at MIT and a member of the Koch Institute, are the senior authors of the new study, which appears today in Science Advances. Morteza Sarmadi, a research specialist at the Koch Institute and recent MIT PhD recipient, is the lead author of the paper.

Staggered drug release

The researchers first described their new microfabrication technique for making these hollow microparticles in a 2017 Science paper. The particles are made from PLGA, a biocompatible polymer that has already been approved for use in medical devices such as implants, sutures, and prosthetic devices.

To create cup-shaped particles, the researchers create arrays of silicon molds that are used to shape the PLGA cups and lids. Once the array of polymer cups has been formed, the researchers employed a custom-built, automated dispensing system to fill each cup with a drug or vaccine. After the cups are filled, the lids are aligned and lowered onto each cup, and the system is heated slightly until the cup and lid fuse together, sealing the drug inside.

This technique, called SEAL (StampEd Assembly of polymer Layers), can be used to produce particles of any shape or size. In a paper recently published in the journal Small Methods, lead author Ilin Sadeghi, an MIT postdoc, and others created a new version of the technique that allows for simplified and larger-scale manufacturing of the particles.

In the new Science Advances study, the researchers wanted to learn more about how the particles degrade over time, what causes the particles to release their contents, and whether it might be possible to enhance the stability of the drugs or vaccines carried within the particles.

“We wanted to understand mechanistically what’s happening, and how that information can be used to help stabilize drugs and vaccines and optimize their kinetics,” Jaklenec says.

Their studies of the release mechanism revealed that the PLGA polymers that make up the particles are gradually cleaved by water, and when enough of these polymers have broken down, the lid becomes very porous. Very soon after these pores appear, the lid breaks apart, spilling out the contents.

“We realized that sudden pore formation prior to the release time point is the key that leads to this pulsatile release,” Sarmadi says. “We see no pores for a long period of time, and then all of a sudden we see a significant increase in the porosity of the system.”

The researchers then set out to analyze how a variety of design parameters, include the size and shape of the particles and the composition of the polymers used to make them, affect the timing of drug release.

To their surprise, the researchers found that particle size and shape had little effect on drug release kinetics. This sets the particles apart from most other types of drug delivery particles, whose size plays a significant role in the timing of drug release. Instead, the PLGA particles release their payload at different times based on differences in the composition of the polymer and the chemical groups attached the ends of the polymers.

“If you want the particle to release after six months for a certain application, we use the corresponding polymer, or if we want it to release after two days, we use another polymer,” Sarmadi says. “A broad range of applications can benefit from this observation.”

Stabilizing the payload

The researchers also investigated how changes in environmental pH affect the particles. When water breaks down the PLGA polymers, the byproducts include lactic acid and glycolic acid, which make the overall environment more acidic. This can damage the drugs carried within the particles, which are usually proteins or nucleic acids that are sensitive to pH.

In an ongoing study, the researchers are now working on ways to counteract this increase in acidity, which they hope will improve the stability of the payload carried within the particles.

To help with future particle design, the researchers also developed a computational model that can take many different design parameters into account and predict how a particular particle will degrade in the body. This type of model could be used to guide the development of the type of PLGA particles that the researchers focused on in this study, or other types of microfabricated or 3D-printed particles or medical devices.

The research team has already used this strategy to design a self-boosting polio vaccine, which is now being tested in animals. Usually, the polio vaccine has to be given as a series of two to four separate injections.

“We believe these core shell particles have the potential to create a safe, single-injection, self-boosting vaccine in which a cocktail of particles with different release times can be created by changing the composition. Such a single injection approach has the potential to not only improve patient compliance but also increase cellular and humoral immune responses to the vaccine,” Langer says.

This type of drug delivery could also be useful for treating diseases such as cancer. In a 2020 Science Translational Medicine study, the researchers published a paper in which they showed that they could deliver drugs that stimulate the STING pathway, which promotes immune responses in the environment surrounding a tumor, in several mouse models of cancer. After being injected into tumors, the particles delivered several doses of the drug over several months, which inhibited tumor growth and reduced metastasis in the treated animals.

The research was funded by the Bill and Melinda Gates Foundation.